Technology

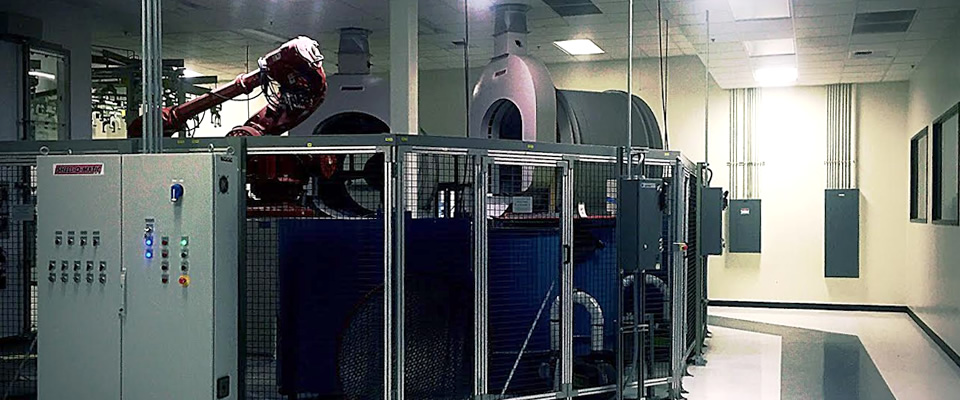

ACT has incorporated the latest equipment and process control systems throughout every department. The ability to maintain extremely tight controls in every phase of the manufacturing cycle allows us to match the ever growing demands of OEMs for improved product performance. The foundation for our extraordinary competencies for manufacturing the most complex geometries lies in our proprietary shell system, which expedites the shell build, facilitates shell removal and creates exceptional fine grain structures.

All major equipment and floor operations are connected to our ERP system for instantaneous information back to our engineering and management staff in order to control quality and mold by mold continuity.

We also offer all the latest prototyping ability from printed wax and core, Quickcast SLA and DMLS for various iterations before tooling is completed for form, fit and function purposes.